CAPABILITIES

With expertise spanning both software and equipment design, we have the skills, experience and resource to seamlessly integrate an array of technologies, systems and products for the best outcomes.

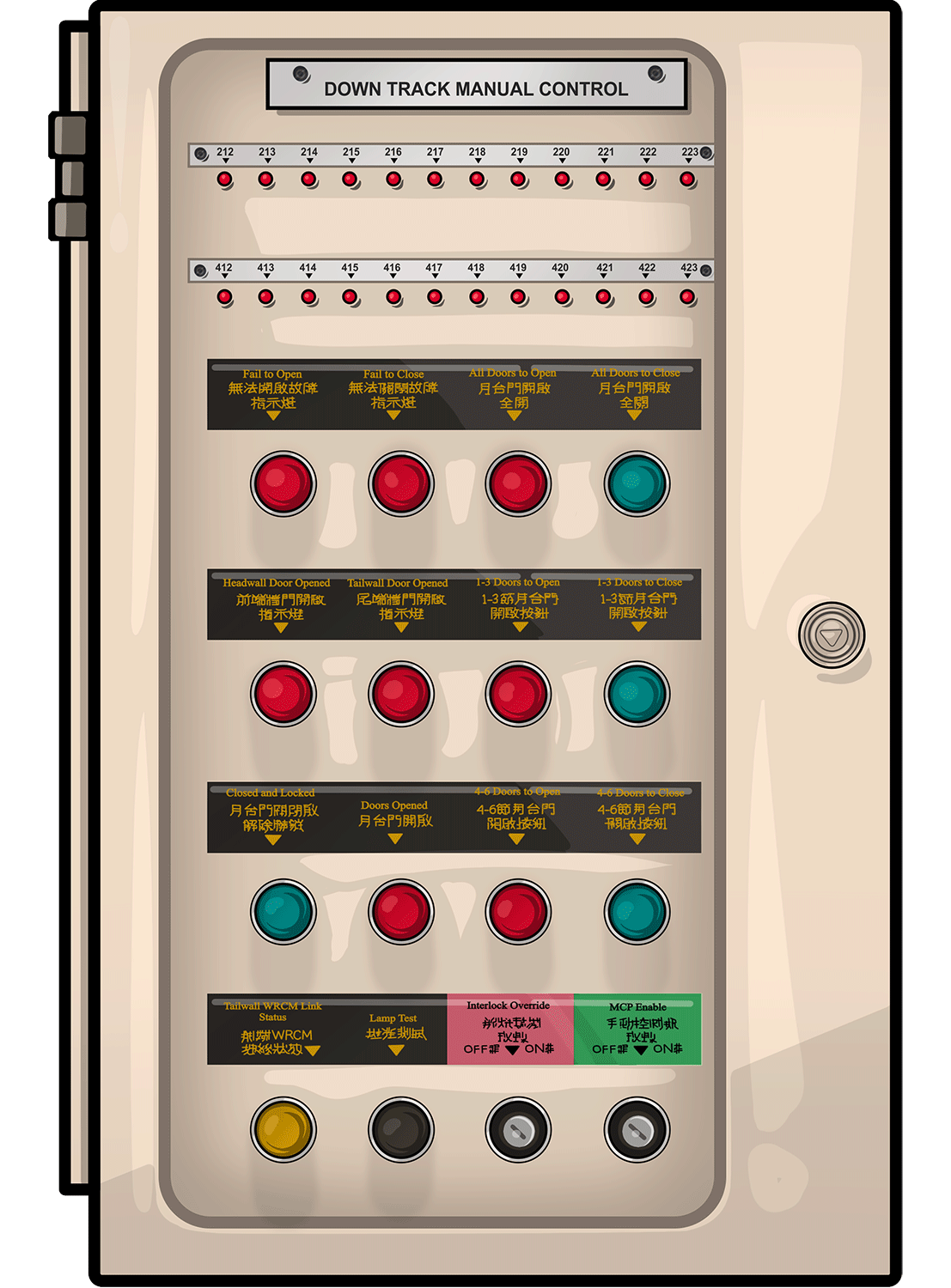

Automation and software design

PLC Programming sits at the core of what we do, and with years of programming experience, we can deliver on anything from small footprint single PLCs to entire production line control. Increased connectivity is the future of manufacturing, and today’s PLCs can integrate from top floor to shop floor.

Our robust, well-written code reduces downtime on equipment, and our systems come with intuitive, password protected interfaces tailored to your specifications. All of which can be implemented safely and securely at your facilities with minimum disruptions.

Hand in hand with PLC programming, we also provide LabVIEW solutions to industry. Developed for use in the field of test, its flexible approach makes it a perfect choice for both test and automation environments.

With excellent hardware connectivity and integration of Microsoft products such as Excel and Word, we’ll help you utilise the power of LabVIEW and identify the right technology for your company.

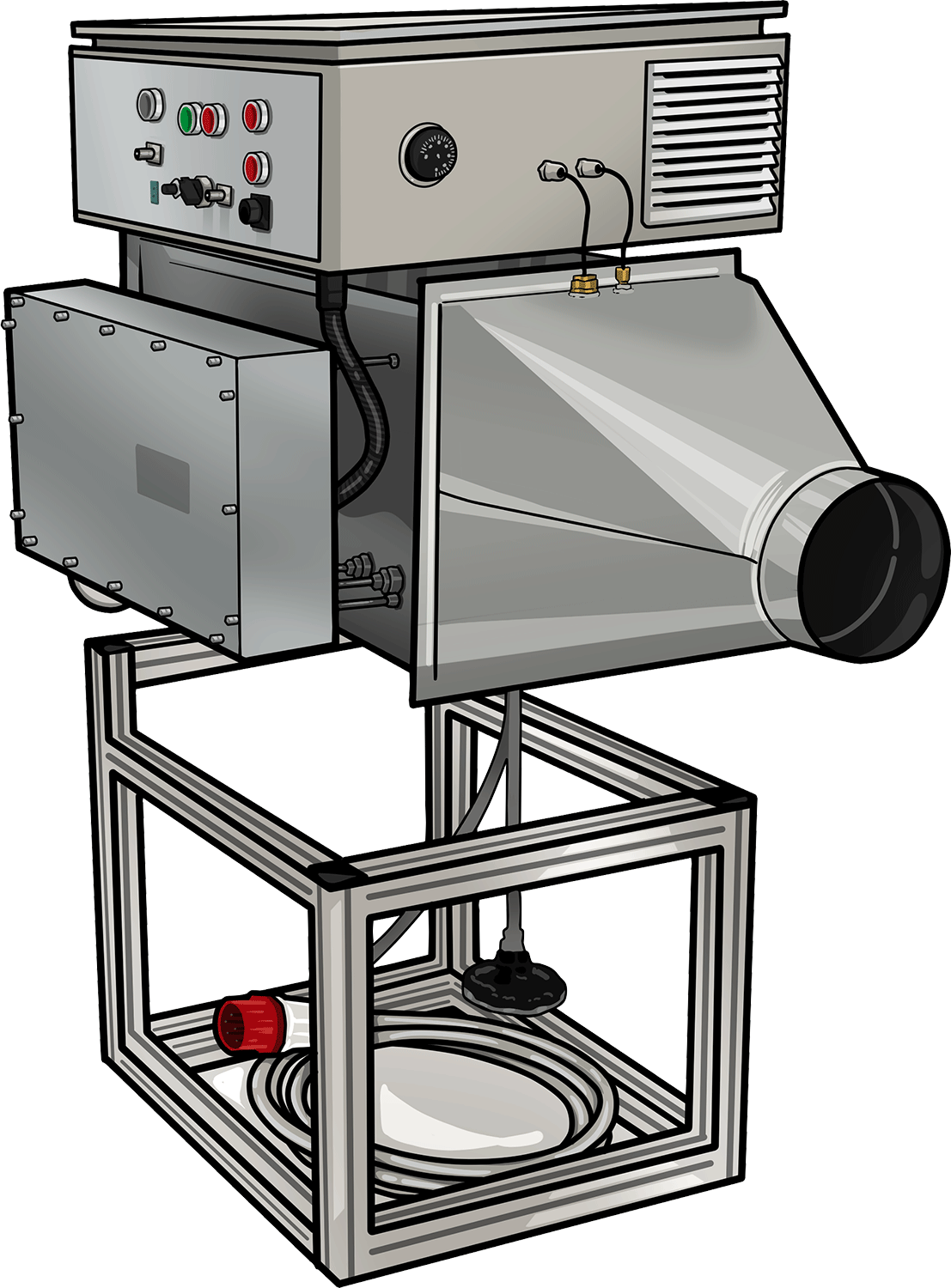

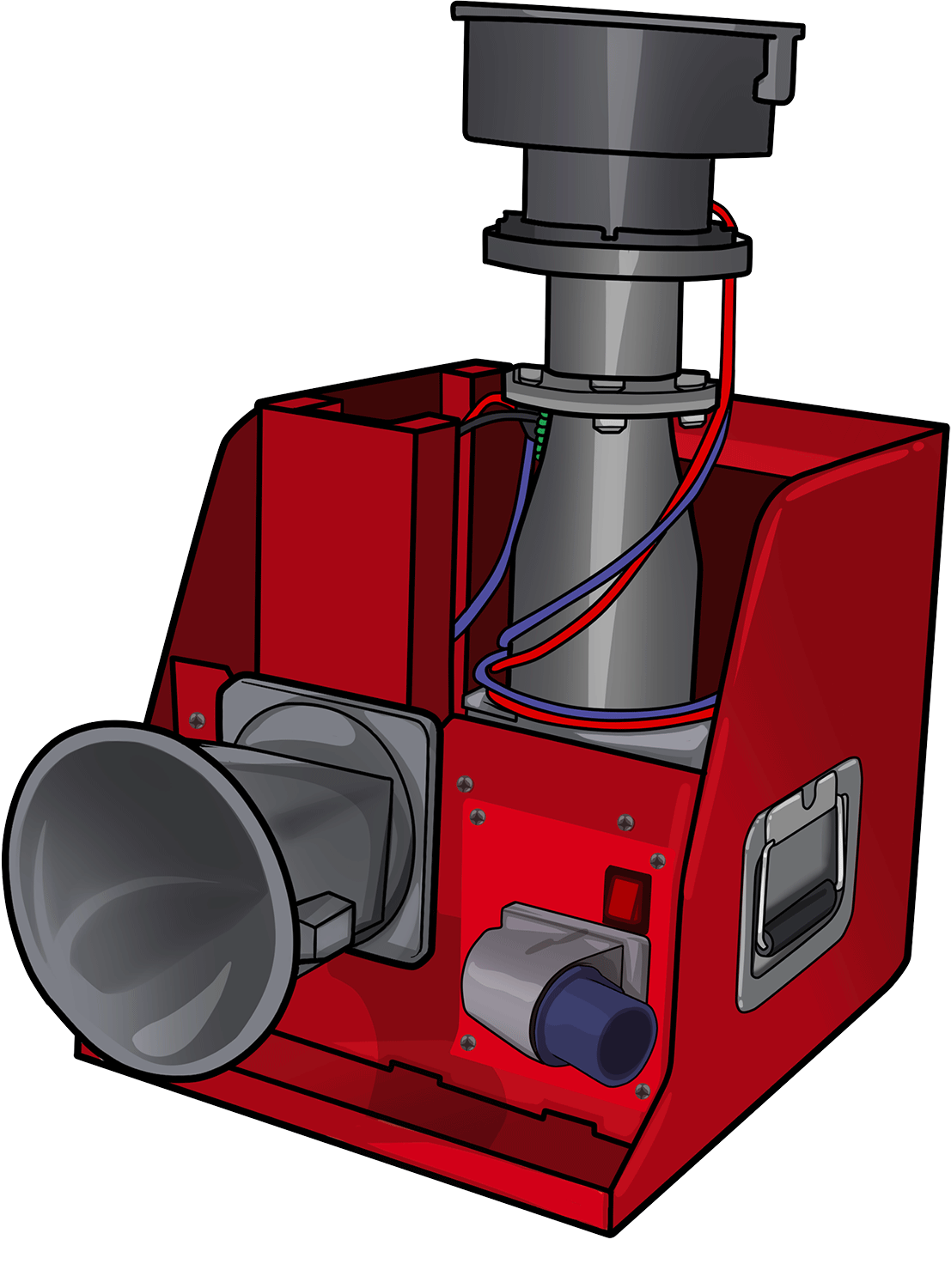

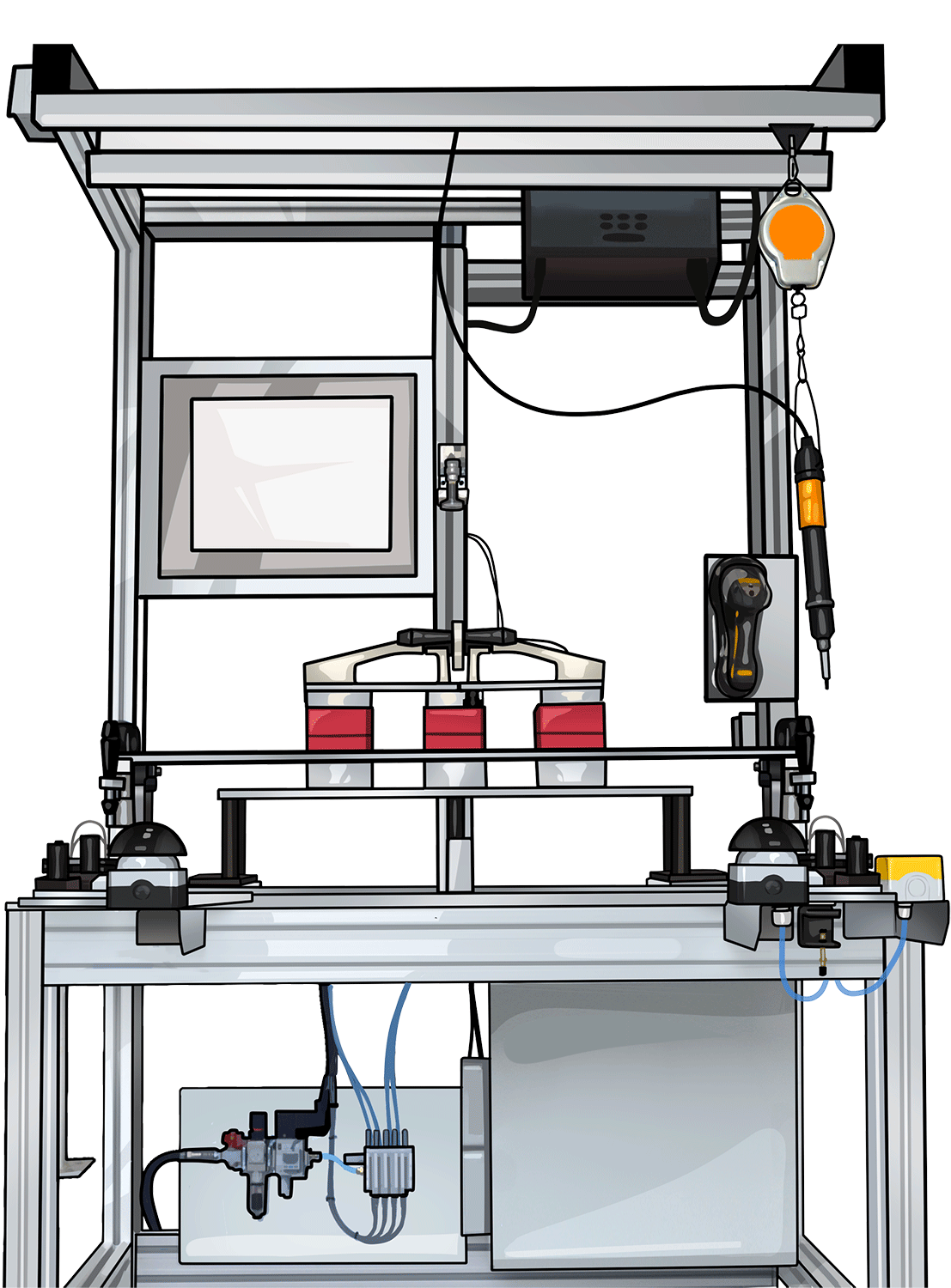

Equipment design and supply

In addition to software, we design and supply equipment and products —from refining the functionality of a process to developing entirely bespoke equipment to meet your requirements.

Joining your team in-house, we can manage your project from its earliest stages to completion, offer guidance on problems you might be facing, and provide recommendations for improvements at any stage of the product development process.