Project Description

07.2018

Mahle filtration is part of the Mahle Group, manufacturing filters for engine applications to increase efficiency and reduce emissions.

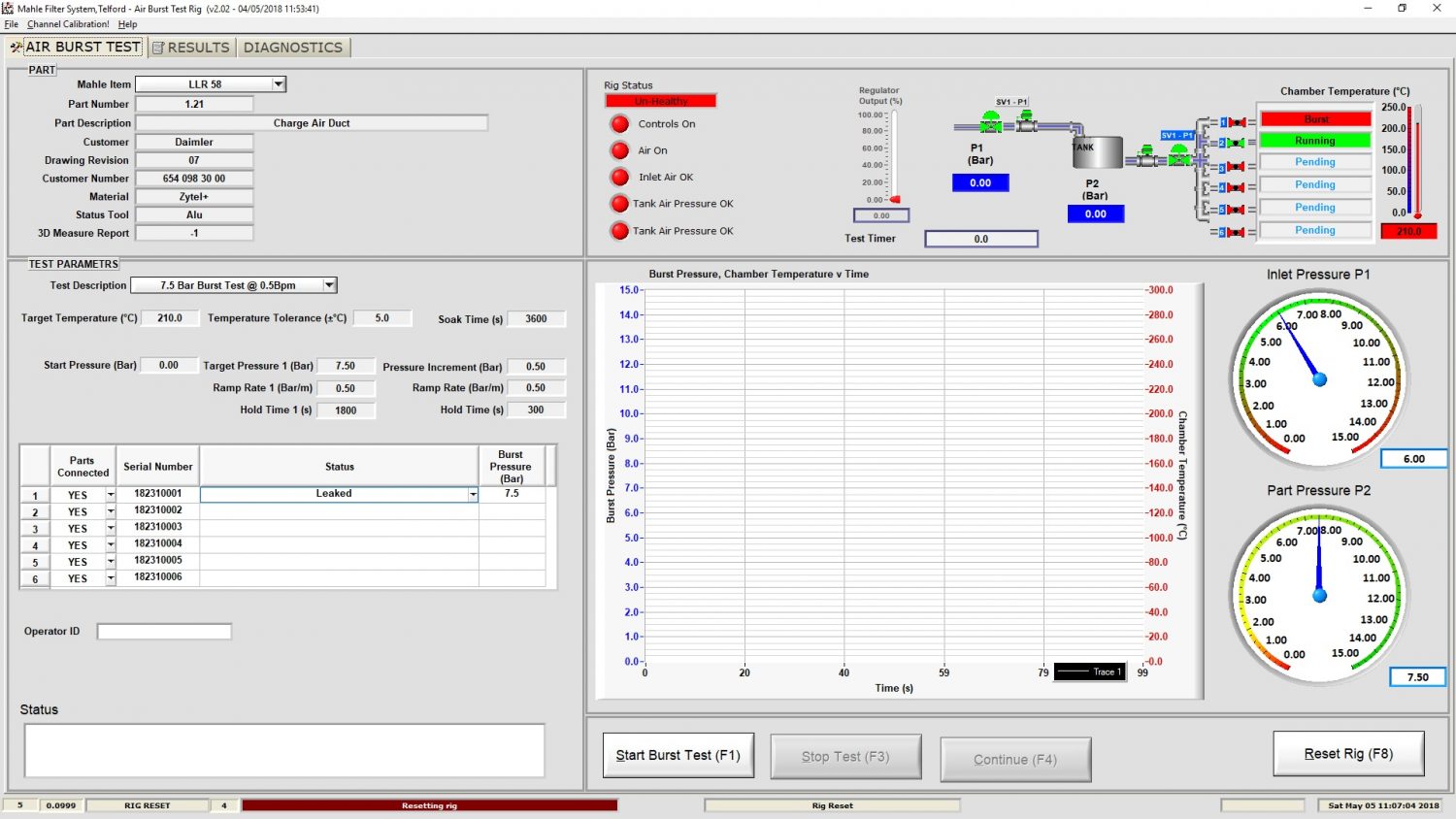

While developing a new product, Mahle approached us to design and supply test equipment to prove its bonded strength.

After comprehensive discussions, we delivered equipment capable of bursting test products to destruction and record the point of failure.

Up to four components are loaded into a proprietary temperature chamber and a pressure profile is applied to each unit under test. Data is logged to a database for post-analysis.

A free-standing enclosure houses electrical and pneumatic control equipment, all of which are controlled from a bespoke application running on a desktop PC. The control enclosure is interfaced to the temperature chamber and controls the tests automatically.