Project Description

Synergy

11.2013

UK company, Synergy required a PC-based control system to control a stretch bending machine. Both hydraulic and pneumatic cylinders provided the machine’s bending motions, and they therefore needed a flexible approach for the user to program this combination of motions.

A standard desktop PC running a LabVIEW application provided the solution for the machine control. The PC was then coupled with an industrial touchscreen and a National Instruments compact DAQ chassis.

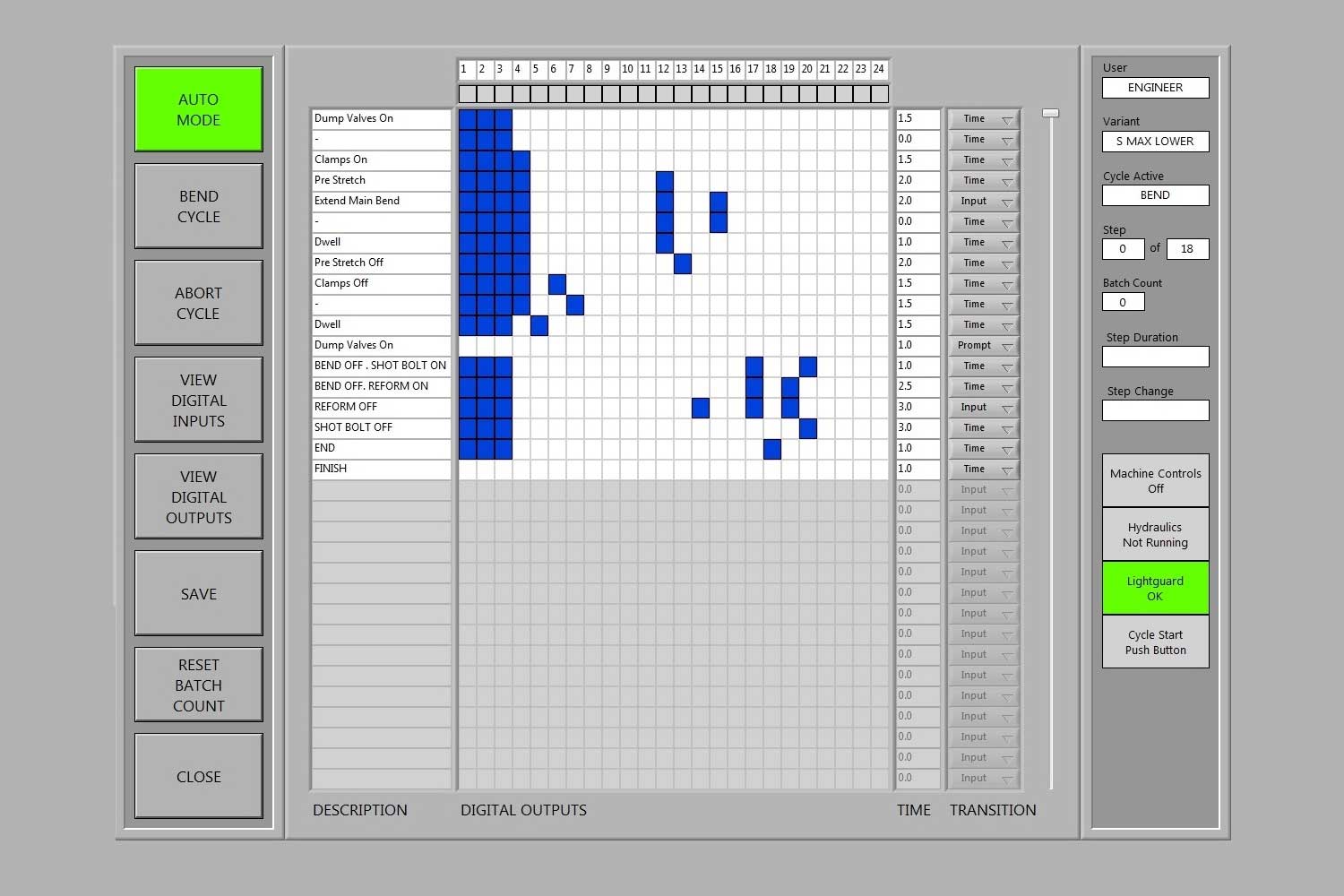

The application we provided is based around a matrix which enables the user to decide the motions required on each step, and the transition needed to continue to the next step.

A sequence can be put together either through the application front end or through a provided excel template, which can then be loaded, and subsequently modified and re-saved if required. This provides the option of offline and online programming of variants.

This approach means the system is capable of running multiple variants and has ability to create new ones.

A separate operator console houses the PC control system, which is then connected to the main machine using Mil Spec plug and sockets. This allows the PC equipment to potentially be coupled up to repeat machines, reducing the need to duplicate the PC control system