Project Description

Rencol Components

01.2015

Rencol Components have designed, developed and manufactured plastic and metal components for almost a century. They approached us for help in automating the analysis of their tolerance rings.

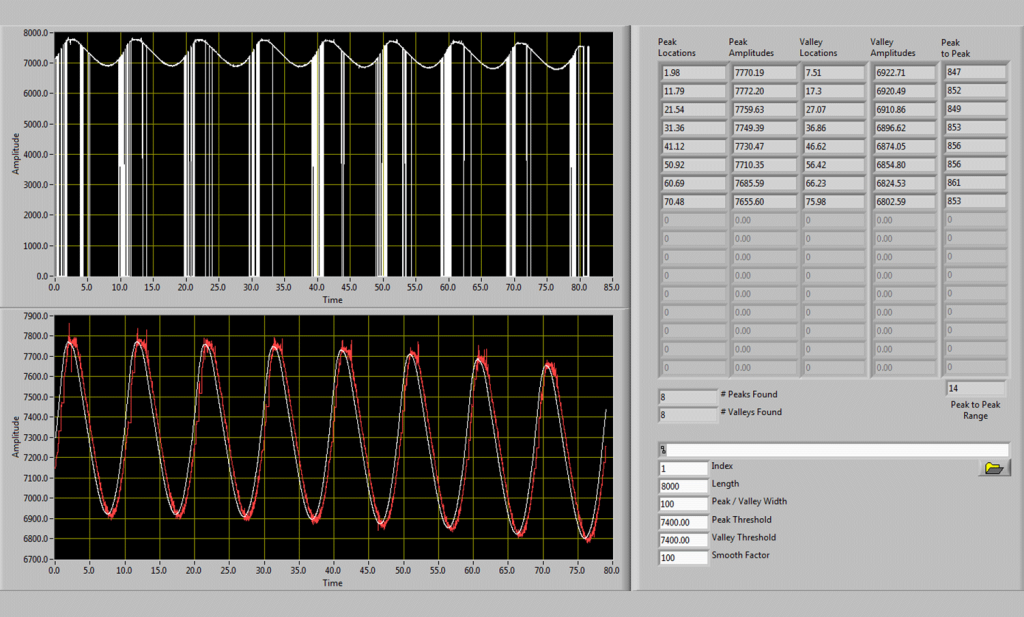

We designed equipment that measures the pressed ridges of tolerance ring strips using a matched pair of Keyence 2D laser distance measuring heads and a servo motor drive slide. A PC running a LabVIEW application controls the connected equipment and performs the strip analysis.

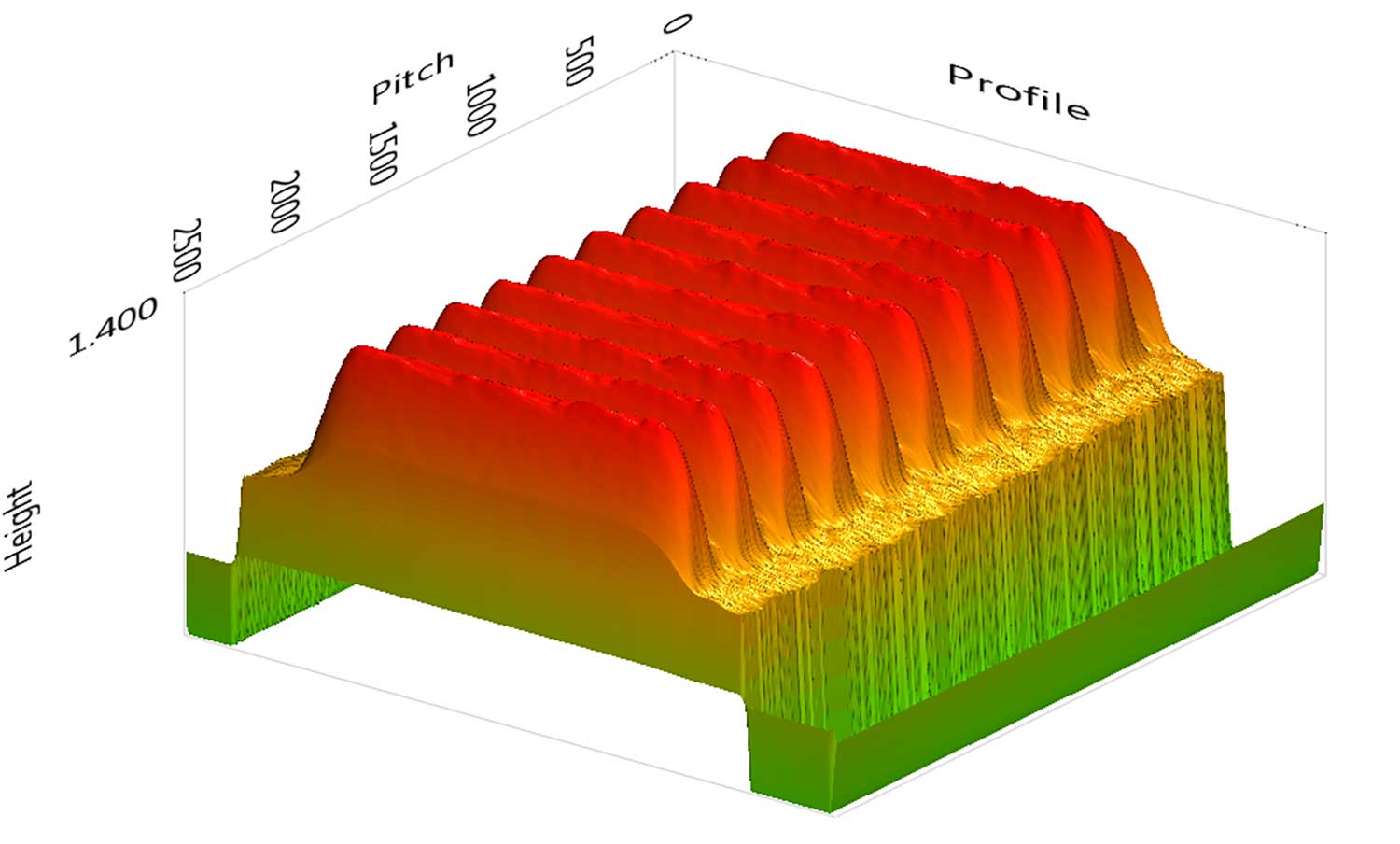

A manufactured strip sample is mounted and clamped to a precision servo motor driven slide, which has an accuracy of 5 microns. The Keyence measuring heads are set to scan 800 points across a width of 40mm with a height accuracy of 2 microns. The strip passes between the laser heads, and measuring the top and bottom of the strip gives the ability to take out the natural twist of the product.

The height, width, pitch and thickness of strips is analysed and tested against user-definable tolerances to determine whether the product passes or fails.