Project Description

JSK Ultrasonics

05.2017

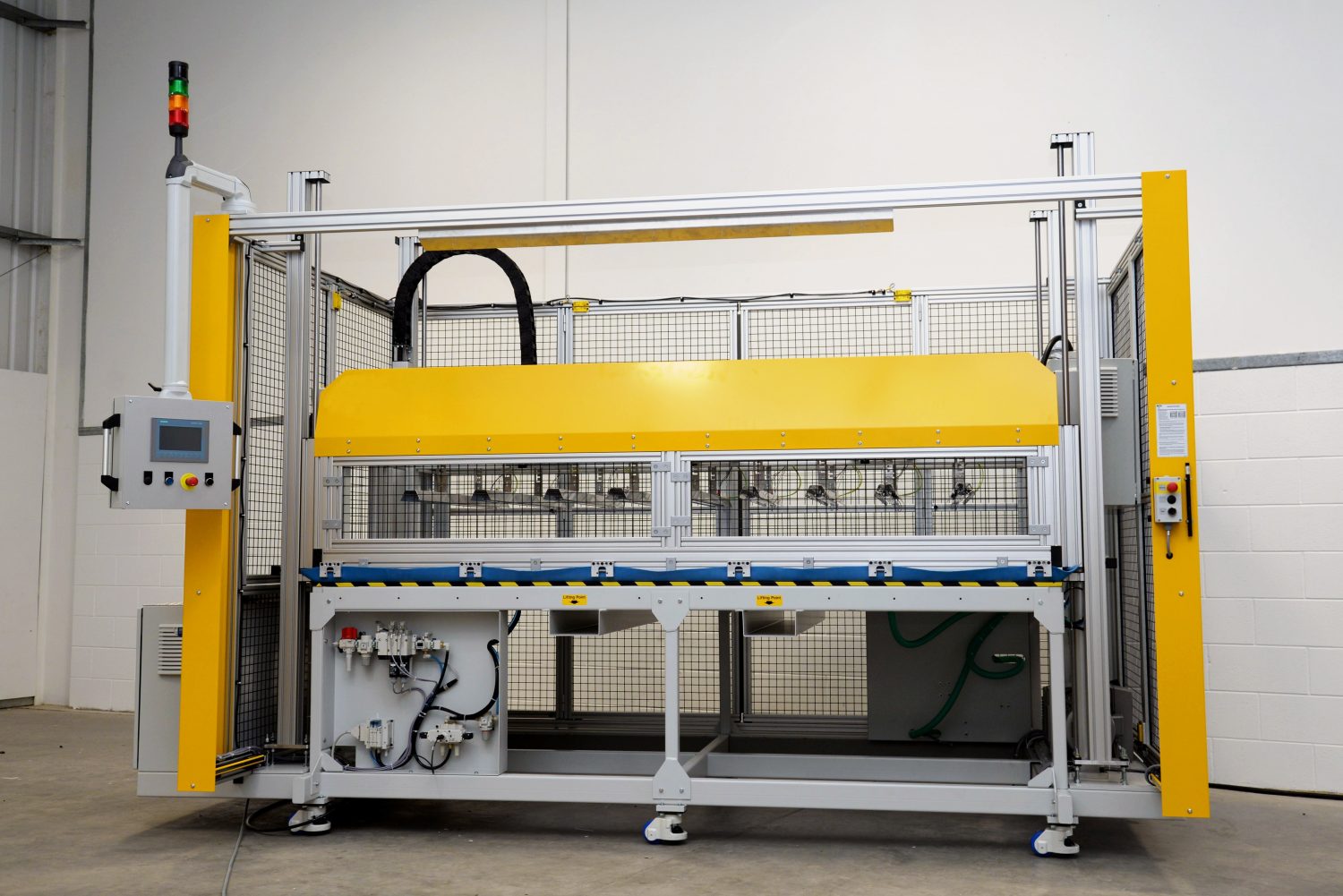

Partnering with industry-leading manufacturer of vacuum forming presses, JSK Ultrasonics, we developed a control system which is now used across their entire range of equipment.

Using the efficiency and fast response times of infrared emitters, we developed a versatile process that can be used across a broad range of forming applications typically found in the automotive trim sector.

The control system is PLC-based and has evolved in line with industry advances to use the latest family of safety PLCs. This reduces the complexity of control panel hardware, and displays extended status of the equipment’s safety system to the user.

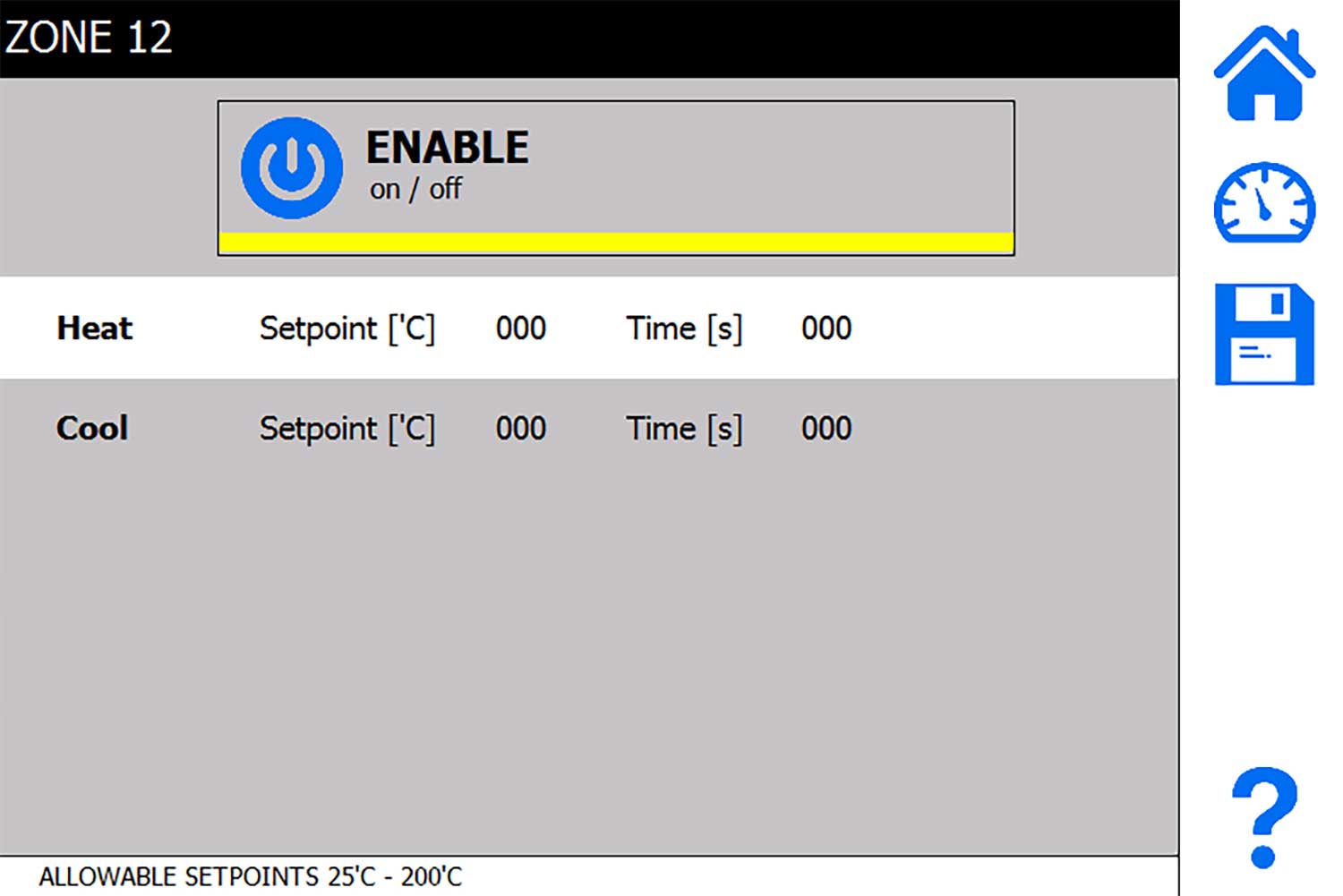

Presses are arranged into heating zones and each individual zone is accurately controlled using PID loops to achieve optimum conditions.

In line with the machine control, we developed an intuitive user interface that’s easy to navigate, and increased the equipment’s flexibility using recipe handling.

The control system continues to be a robust, reliable and adaptable solution that has become the standard in manufacturing facilities.